Objectives/Background

Research Objectives

RESEARCH OBJECTIVES IN THE THIRD FUNDING PHASE (2020-2023)<

Single crystal Ni-base superalloys represent key materials for turbine blades in modern gas turbines for aero engines and power plants. International mobility and global energy supply rely on this fascinating class of high temperature materials. Improvements in efficiency and emissions demand new concepts in single crystal technology, which require progress in four areas of expertise:

A basic understanding of all aspects of alloy design and performance. This comprises the role of heterogeneities, both on a large scale (dendritic and interdendritic regions) and small scale (gamma / gamma prime microstructure). It includes the exact role of alloying elements (especially: d-shell elements). It is important to understand how microstructural and atomistic parameters affect thermodynamic equilibria, the evolution of microstructure during processing and high temperature deformation. Focus is on creep and fatigue deformation and damage mechanisms, microstructural stability (nucleation and growth of new phases, coarsening of the gamma / gamma prime microstructure), castability (porosity, parameters of the dendritic structructure), heat treatments and HIP, surface integrity (oxidation and coatings) and rejuvination. We are consider new alloy compositions with better performance which also reflect the need to make most efficient use of global ressources. Target alloy compositions must also reflect the availability a possible scarcity of strategic elements (e.g. less Re, more Ru, W, Mo and others). In addition to Ni-base superalloys, Co-based single crystal super alloys with gamma / gamma prime microstructures will also be considered.

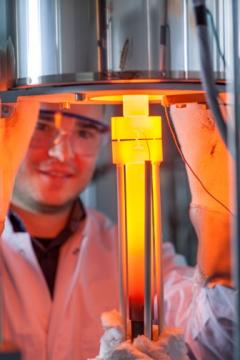

The continuous improvement and innovation of processing technologies for establishing specific nano and micro structures with a better homogeneity and with improved properties (single crystalline solidification in a fluidized bed, additive processing using selective electron beam melting, heat treatments under hydrostatic pressure, coating technologies, rejuvenation procedures).

More detailed knowledge of materials properties and microstructure through use of new test procedures, either mechanical measurements (like miniaturized creep and fatigue testing, shear and circular notched specimen testing, nano metrology) or characterization methods (high resolution, aberration corrected transmission electron microscopy, 3D atom probe, dark field diffraction contrast TEM in scanning mode). These new techniques will help to identify elementary processes which govern the formation of new phases, the microstructural coarsening of the gamma / gamma prime microstructure and the interaction of deformation and damage mechanisms.

Materials modeling bridging all scales, from atomistic (ab-initio-methods, molecular dynamics) to mesoscopic (discrete dislocation modeling and themodynamic/kinetic modeling of microstructural evolution) and macroscopic (physically sound constitutive equations).

The scientific contributions in SFB/Transregio 103 come from different areas of expertise, like materials science and engineering, solid state physics and chemistry, scale bridging materials modeling and processing and manufacturing technology which are in close scientific contact. With this innovative approach, SFB/Transregio 103 researchers aim to make an impact in a key technology, which is important from an economic and science point of view.

...

Experimental Infrastructure

Scale Bridging Modelling

Materials Research at the Ruhr-Universität Bochum

Materials Research at the Friedrich-Alexander-Universität Erlangen Nürnberg

Materials science at the Friedrich-Alexander-Universität (FAU) started in the 1960s with Bernhard Ilschner, a pioneer of high temperature deformation of engineering materials in Germany. Later on Haël Mughrabi made seminal contributions to the field of high temperature strength of single crystal Ni-base super alloys. Today, processing of single crystal super alloys, relation between microstructure and properties and high temperature oxidation form research highlights at FAU. As part of the Initiative for Excellence of the German Federal Government, FAU earned the DFG funded Cluster of Excellence, EXC 315-1, entitled Engineering of Advanced Materials.

...

Data Policy

The experimental and theoretical projects of the SFB/TR103 generate large data sets on processing, on microstructure and on the thermodynamic, kinetic and mechanical properties of single-crystal superalloys. The key to understanding and optimizing the properties of single crystal superalloys is the intelligent and scale-bridging correlation of the data that is highly heterogeneous in content and character. This leads to requirements regarding the storage and interlinking of research data and the corresponding research data management (RDM) at the level of individual projects and at the level of the whole SFB/TR103 consortium. Main elements of data handling at the consortium level are birth-certificates of the experimental samples, a central general-purpose file-server, an RDM panel for establishing a common basis of data management and a cross-sectional group 'Material informatics and machine learning' for coordinating the correlation and utilization of the data. At the project level the solutions are more tailored towards special-purpose application and include commercial and specially developed databases as well as protocols for that standardize the workflows of data exchange. A central aim that is pursued in coordination with national and international RDM activities is to make the research data of the SFB/TR103 available as FAIR data for later scientific usage. The particular challenge is the structured storage of disperse data that range from simulation data at different length and time scales to image information from electron-microscopes and atom-probe tomography to mechanical and micromechanical data from nanoindentation, creep and fatigue experiments.

...